NITROMAX has the most technologically advanced and newest machinery park for carrying out nitriding and nitrocarburizing processes in Poland, produced by Seco/Warwick and Remix.

Our furnaces – machine park

Φ 1200×3000

Φ 1000×2000

Φ 1000×2000

All of these devices have the following components:

- the most advanced computer systems for controlling processes with very high precision in process management (temperature distribution in the working space +/- 3°C)

- the most technically advanced and reliable nitrogen potential control systems from Stange company

- high-efficiency mixing turbine systems that ensure perfectly consistent nitriding results throughout the volume of the charge

- high-performance heating and power control systems that reduce energy consumption

- precise gas dosing systems that ensure the ideal composition of the process atmosphere and limit emissions to the atmosphere.

Laboratory

Laboratory equipment consisting of:

Cutting machine

TOP TECH Alocut 200

Mounting press

TOP TECH Presidon ML 32

Grinder/polisher

TOP TECH Plato EF M1/250

TOP TECH Plato EF M1/250

Metallographic microscope

INNOVATEST IN-MM 600

INNOVATEST IN-MM 600

Microhardness tester Vickers

INNOVATEST Nexus 412D

INNOVATEST Nexus 412D

Portable hardness tester

INNOVATEST MET-U1A/20

INNOVATEST MET-U1A/20

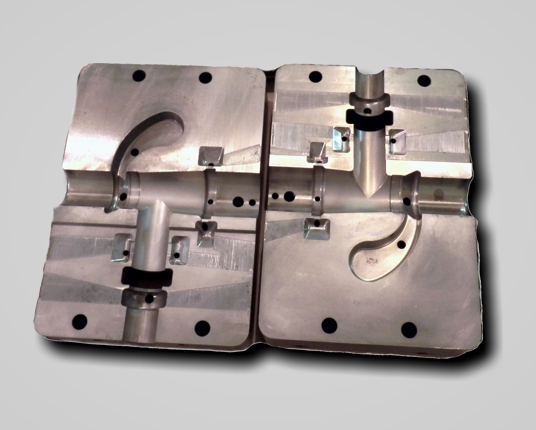

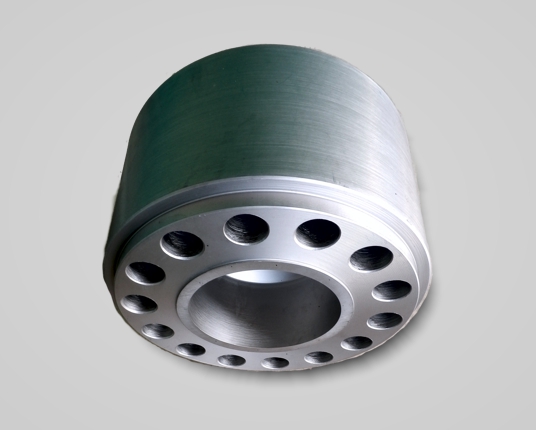

Sample elements processed in NITROMAX company’s operations

- die inserts for aluminum die casting

- shot sleeves systems for die casting

- dies for extruding aluminum profiles

- dies for hot forging

- stamping dies for car body parts

- cutting dies for automotive components

- molding inserts and slides for plastic injection molds

- elements for producing concrete profiles

- screws and barrels for injection molding and extrusion machines

- drive shafts

- rolls for rolling mills

- crankshafts and camshafts

- automotive components

- gears and gear shafts

- hydraulic power components